Tungsten copper bar is a combination of tungsten and copper. The manufacturing process is as follows: press the refractory metal, sinter the pressed compact at a high temperature, and infiltrate it with copper. All this is done under very closely controlled conditions. The result is a relatively hard material with superior arc and wear resistance, high physical Properties: at elevated temperatures, and good electrical and thermal conductivity.

| Availability: | |

|---|---|

| Quantity: | |

tungsten copper rods

Jinxin

Product Description

Tungsten copper alloy (W-Cu alloy) is the composite of tungsten and copper which own it excellent performance of tungsten and copper. It is used widely in such industries as engine , electric powder, electron, metallurgy, spaceflight and aviation.

Tungsten copper alloy round rod: the manufacturing processes of it are static pressure molding, high temperature sintering, soluble copper infiltration.

Tungsten copper rod specification:

Diameter> =0.9mm

Length<=300mm

Because of the high eletrical conductivity and low consumption, tungsten copper bars are widely used to make Grid siderod, Lead, Support, Electrode for the Gas discharge lamp.

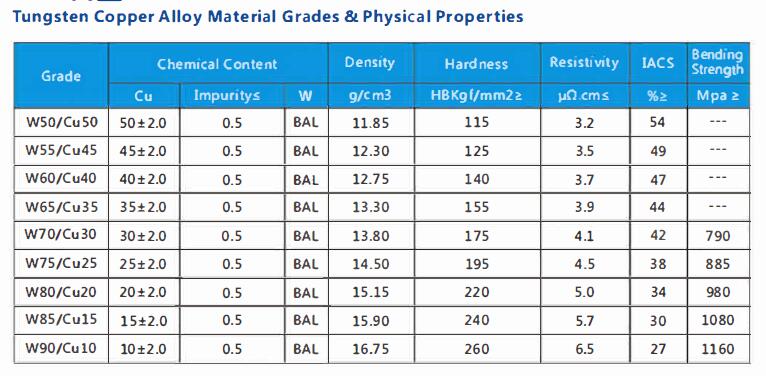

Tungsten copper bar owns not only the low expansion of tungsten and high heat conductivity of copper. Its expansion index and heat conductivity can also be changed through changing the content of the materials, which provides convenience to the using of the material.We can supply various specifications and the tungsten copper alloys with different tungsten proportions.

.